HOME | home

Iron on the Hearth | Iron, Cast and Forged | Cast Iron Cooking 4 | Copperware | Copper and Brassware 2 | Brass Alcohol Stove | Pipe Smoking | Tobacco the Indian Weed | Women's Pipes | Clay Pipe Collection | Pipes2 | pipes3 | Pipes4 | Pipe Tampers | Early Lighting 1 | Early Lighting 2 | Early Lighting 3 | Early Lighting 4 | Early Lighting 5 | Early Lighting 6 | My Lamps | Center Draft Lamps | Center Draft Lamps II | Center Drafts III | Miners lamps | Matches and Match Safes

Iron, Cast and Forged

Iron 3

Pictured above, one forged, flesh fork from Maine, another from Pennsylvania and a betty lamp from the Boyle collection.

|

The Blacksmith's Art

Before the machine age the village blacksmith was indispensable in the community. He was a man who could make or mend the tools needed to survive. In America there was an abundance of iron ore available close to the surface that could be mined. It was not long before iron furnaces appeared near many of the settled areas in the colonies. This provided the American blacksmith the iron he needed. If all raw iron was imported from Europe it would have been very expensive indeed. Many household items used until the late 19th Century where hand-forged iron. It should be noted that most of the time blacksmiths did not shoe horses. This was done by another tradesman, the ferrier.

The blacksmith was important to a settlement for his skills to both manufacture and repair metal items. A country blacksmith produced harrows, rakes, plows, scythes and other farming tools. Nearly all blacksmiths made kitchen tools and utensils for fireplace cooking, lighting devices, smoothing irons, building hardware and woodworking tools. So important were the services of the blacksmith that many settlements offered free land, a home and a shop as incentive to settle in a particular village or town. A dedicated, hardworking blacksmith usually had enough work that he was able to be a full-time tradesman and did not have to farm on the side to survive. As time went by, many blacksmiths became town leaders and were wealthy in comparison to other tradesman represented in a village.

A blacksmith did have to work long, strenuous, hot hours to make his living, however. The work required stamina and the ability to tolerate allot of heat during backbreaking sessions over a fire. Repairing iron items was as important as making new goods for sale. Skill in mending could set one blacksmith apart from another. Metalware was very valuable. If a kettle or plow was broken no one discarded it. They were artfully repaired by hand. kettles and pots were often amongst the most valuable processions in a household. They were frequently passed down through the generations. The art of the blacksmith was not only functional it was often very beautiful. A well trained smith could work iron to appear as delicate as lace. A fork might terminate in a rat tail with a lovely spiral or a set of fire tongs might have detailed handles carefully designed with comfortable yet decorative hand grips. Sometimes brass or other metals were inlayed in the iron for decorative purpose. This process is called "bidri". All sorts of wonderful joints and hinges were employed in detachable pot lifters and lighting devices. Some ironwork was finished to a higher standard with a polished surface. This work was done by a whitesmith. The word 'whitesmith' traditionally refers to a smith who, instead of leaving the finished product black, files and polishes his products to a reflective, or "white" luster.

Getting dietary iron from cooking pots - Science Update - Brief Article

Agricultural Research, July, 2003

In trying to explain why certain rural populations in China experienced less iron deficiency anemia than other groups, researchers noted that those without anemia tended to use more iron pots in their cooking. So studies were undertaken in which cabbage was cooked three ways following a common recipe from northwest China. Using both aluminum and iron pots, researchers cooked fresh Chinese cabbage, fresh Chinese cabbage with vinegar, and fermented Chinese cabbage (sauerkraut). Analysis of the cooked cabbage--using a revolutionary, ARS-developed "fake gut" that simulates human digestion--to determine actual bioavailability of the iron showed that all the dishes cooked in iron pots had higher levels of biologically available iron than those cooked in aluminum ones. Adding vinegar or cooking already acidic foods, such as sauerkraut, also seemed to cause more iron to leach from the pots and make it more available for absorption. The work was done cooperatively with scientists from Cornell University's Division of Nutritional Sciences. Raymond P. Glahn, USDA-ARS U.S. Plant, Soil, and Nutrition Research Laboratory, Ithaca, New York; phone (607) 255-2452, e-mail rpg3@cornell.edu.

|

Cast Iron

Iron had been made in Britain since Roman times, but in small quantities and using charcoal to smelt the ore so most early foundries were small, woodland-based enterprises close to sources of wood and ore, such as in the Forest of Dean and the Weald. The first improvement in technique came with the introduction of the blast furnace, where air was forced into the fire by bellows to increase the temperature. The first record of such a furnace comes from the Weald in 1496. The switch from charcoal to coal and coke in England meant production moved from the forests to the coalfields, with South Wales, Scotland, Staffordshire and Shropshire becoming the key centers. This significant development in the production of cast iron is credited to an English iron-founder named Darby in 1730, the discovery and production of coke lowered the cost of producing cast iron. In the American colonies the use of charcoal from burning hardwood persisted in many areas fairly late due to the abundance of trees.

Sand casting has existed for many hundreds of years. The basic technique of sand casting iron cookware has changed little over time. The foundry pours molten iron into a mold created in sand to create a piece in a particular design. The mold is created by packing sand, very artfully, around a pattern, often made of wood. When this pattern is removed from the sand it creates the area to be filled with iron in the exact shape of the wooden model. It is in this void the molten iron flows. Amazing detail can be achieved by a skilled artisan. Binders are used mixed in the sand to make the mold hold together long enough for the founder to pour and serves to hold precise detail in the sand. There are many formulas for binders often with clay as a component.

Minor changes in the casting process can show us the approximate date of a piece. The oldest pieces will have a circular "sprue" mark on the underside of the piece. This technique was used until the mid-to late 1700's. Most pieces were cast upside down, to avoid having an unsightly sprue or gate marks on the top of the piece. The sprue is the point where the foundryman poured the molten iron into the mold. It is a sort of pipeline for the metal to flow into the mold itself. Any piece that is cast, even those today, will have at least one point where you can see where the iron entered the mold. Sometimes it is well ground and polished down but you can still find it most of the time.

Typical gate mark on an iron posnet

Many of the pots in use during the late 1700's were designs that evolved from patterns once cast in bronze or bell metal as it is sometimes called. Bronze conducts heat better than iron but vessels made of bronze are far more costly to produce. With the change in metals, the shapes of cooking vessels changed somewhat with the function and the fashion. They mostly remained fairly close to their original forms so one can see how the line of succession progressed. Posnets and three legged kettles continued relatively unchanged all the way into the late 19th Century and very closely resemble the original shapes.

This next generation of cast iron, beginning around the mid 1700's, have a "gate" mark, which looks like a long thin line on the bottom of the piece. This is where the iron entered the mold, and the technique lasted from the mid-1700's to the late 1800's or so. Pieces made around 1875 to the present time were engineered so the iron entered the mold from the sides. It entered usually in two places, sometimes opposite one another. These pieces have a smooth bottom. Current techniques have the iron coming in from the side, so look for one or more places on the sides of the iron pot with heavy grinding marks where the iron entered the mold. The grinding is done to finish the piece so that no unsightly burs or roughness mars the surface. This is a fairly modern development brought about by the ability to cheaply grind ironware. This would have wasted too much valuable time and been next to impossible for an 18th or early 19th Century founder to carry out.

Between 1875 and 1940, cast iron cookware manufacturers refined their casting techniques to produce extremely well-made pieces. The earliest pieces (1875 to 1900) were thinner than those produced later. Unfortunately this thinning of the walls led to a high number of pieces either cracking or warping when used over a flame. Pieces produced during this time where also manufactured with fewer finishing steps, in production. It is not difficult to notice many of these pieces of ironware have a slightly more primitive appearance. About this time many forms of iron cookware became largely obsolete. The pieces designed for cooking over a hearth or outdoors became less important and pieces designed to be used on a wood stove or gas stove as well as in an oven began to take over.

Three cast iron pieces in the Boyle Collection

Major manufacturing improvements where soon made in the trade and iron pieces made between 1900 and 1940 were both slightly thicker and more finished in their appearance. The quality of the production process reached its pinnacle between 1920 and 1940. During this time, the manufacturing included a series of polishing steps that produced pieces with glass-like surfaces. One major development used by manufacturers was to tumble the finished product in a large rotating drum that contained small bits of metal (usually star shaped) that polished the cast iron pieces. Some iron cookware, such as skillets or Dutch ovens, were turned on lathes to provide a very smooth cooking surface. One can often see the lathe marks on the inside of these pieces. Two of the most well known manufacturers with recognizable names are Wagner and Griswold. After around 1940 both Griswold and Wagner were no longer controlled by family members, and sadly the quality in the wares produced deteriorated significantly. Pieces made after 1940 are downright clunky in appearance and do not have the same high quality finish. You can tell these pieces from a distance due to their thicker skillet walls and course looking castings.

Much of the cast iron for sale today is made in China and varies in quality. Some of the iron imported is quite well made while other pieces are just not worth owning. Lodge still makes very nice ironware and some people prefer to purchase all newly cast cookware. Lodge has been in business since 1896.

Troy enjoys a bit of raw cabbage

Iron for Health

Iron is vital to the health of the human body, and is found in every human cell, primarily linked with protein to form the oxygen-carrying molecule hemoglobin. The human body contains approximately 4 grams of iron. Dietary iron comes in two forms: heme iron and non-heme iron. Heme iron is found only in animal flesh, as it is derived from the hemoglobin and myoglobin in animal tissues. Non-heme iron is found in plant foods and dairy products. Iron serves as the core of the hemoglobin molecule, which is the oxygen-carrying component of the red blood cell. Red blood cells pick up oxygen from the lungs and distribute the oxygen to tissues throughout the body. The ability of red blood cells to carry oxygen is attributed to the presence of iron in the hemoglobin molecule. If we lack iron, we will produce less hemoglobin, and therefore supply less oxygen to our tissues. Iron is also an important constituent of another protein called myoglobin. Myoglobin, like hemoglobin, is an oxygen-carrying molecule, which distributes oxygen to muscles cells, especially to skeletal muscles and to the heart. Iron also plays a vital role in the production of energy as a constituent of several enzymes, including iron catalase, iron peroxidase, and the cytochrome enzymes. It is also involved in the production of carnitine, a nonessential amino acid important for the proper utilization of fat. The function of the immune system is also dependent on sufficient iron. Although the human body conserves iron very well by reusing iron from old red blood cells to make hemoglobin for new red blood cells, iron deficiency is one of the most common nutrient deficiencies in the United States and around the world. Poor iron status may be caused by inadequate dietary intake, poor absorption, parasitic infection, and/or medical conditions that cause internal bleeding. People who donate blood regularly, women with excessive menstrual bleeding, those who use medications (for example, antacids) that interfere with the absorption of iron, and pregnant and lactating women may be at risk for iron deficiency. In addition, the elderly, vegetarians, and children often have inadequate intake of this mineral. Iron deficiency causes microcytic and hypochromic anemia, a condition characterized by underdeveloped red blood cells that lack hemoglobin, thereby reducing the oxygen carrying capacity of red blood cells. But even before iron deficiency anemia develops, people with poor iron status may experience a variety of symptoms including fatigue, weakness, loss of stamina, decreased ability to concentrate, increased susceptibility to infections, hair loss, dizziness, headaches, brittle nails, apathy, and depression. Individuals with poor iron intake may also demonstrate an unusual eating behavior called pica, in which they eat unsuitable and/or inedible materials such as dirt, clay, laundry starch, charcoal, and/or lead paint chips. In children, iron deficiency is associated with learning disabilities and a lower IQ.

|

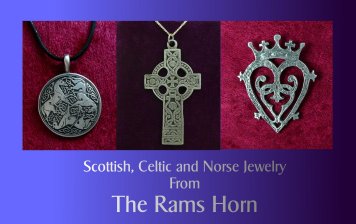

Anvil Jewelry made by James and Beth Boyle in the Rams Horn Rural Life Series

Where you can purchase these pieces hand cast in the USA by James Boyle.

No part of this website may be used for any purpose ( including using images )

without written consent from The Rams Horn